Rubber mouldings possess high adaptability, allowing them to take on any form or shape. It embodies qualities such as toughness, durability, chemical resistance, and flexibility. It finds applications across a spectrum of devices, ranging from heavy-duty machinery to small electrical appliances. Industries, engineering, automobiles, construction, furniture, and even chair and table tips, as well as food processing, actively utilize them.

Rubber mouldings possess high adaptability, allowing them to take on any form or shape. It embodies qualities such as toughness, durability, chemical resistance, and flexibility. It finds applications across a spectrum of devices, ranging from heavy-duty machinery to small electrical appliances. Industries, engineering, automobiles, construction, furniture, and even chair and table tips, as well as food processing, actively utilize them.

Different appliances necessitate distinct mouldings, and a variety of materials are employed in their production. The range of it encompasses compression models, transfer, injection, and rubber-to-metal moulding.

The most economical and straightforward rubber moulding method is the compression moulding process. In this procedure, a sheet of rubber is passed through a machine that compresses it into the desired shape.

Transfer rubber moulding surpasses compression moulding in producing higher-quality rubber. This method involves placing a lump of material in a vessel, and the machine moulds the rubber with force.

The injection moulding process stands out as a preferred and recommended method. It entails a repeated sequence of lowering a syringe into the mould, followed by the machine injecting the rubber into the mould.

The rubber-to-metal bonding process, the final method, employs a range of rubber composites that can adhere to various metals.

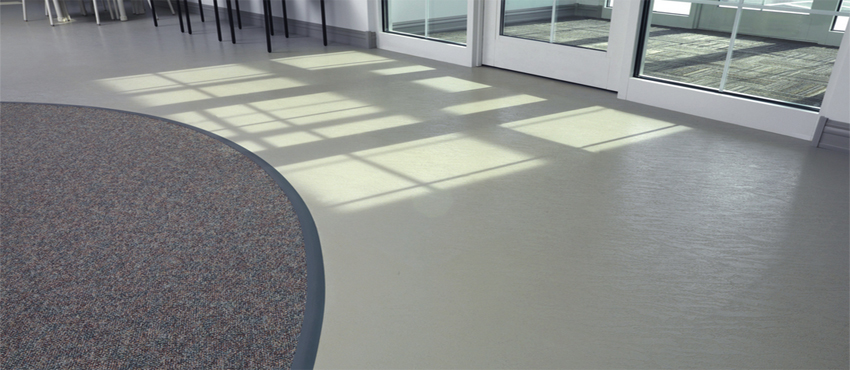

Serve diverse purposes, finding use in creating table and chair leg tips to prevent floor scratches and wear. They also manifest in window and door wedges, ensuring doors and windows remain open during windy conditions. Rubber stoppers, a form of moulding, serve as excellent alternatives to bottle caps. Door stoppers, innovatively designed, prevent door handles from damaging walls when placed behind doors. Oblong buffers are crafted for chairs and beds, safeguarding floors and furniture from dents.

In the automobile industry, mouldings play a crucial role, with rubber mats for cars being easy to use and maintain, keeping vehicles clean from dust and dirt. Various car parts also incorporate moulded rubber components.

Household appliances feature rubber parts produced through both compression and injection methods, serving purposes such as sealing, connecting systems, and damping.

Industrial moulded products include seals, rings, gaskets, grips, caps, bumpers, stoppers, discs, knobs, plugs, rollers, and an extensive array of products. They are indispensable for machines and appliances, ensuring their security and continuous operation. Rubber’s malleability enables it to take on various forms, designs, or shapes, depending on the product. Ultimately, mouldings contribute to a worry-free existence, providing excellent service in safeguarding machines and appliances. Opting for high-quality rubber ensures lasting protection.